Fuel Installation

Fuel tanks

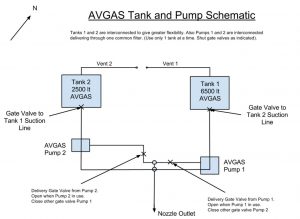

- Two tanks

Tank 1 (Main Tank) 6,724 litres

Tank 2 (Reserve Tank) 2,293 litres

- Two Pumps – Either tank can feed either pump

Tank and Pump schematic

Switching Tanks

Normal operation – Tank 1 feeding Pump 1

Symptoms of low fuel level in the tank

- Fuel flow rate reduces

- Pump labouring and fuel flow ‘surges’

Change from Tank 1 to Tank 2

- Replace fuel nozzle in the pump

- Lift man lid on tank 1

- Move yellow lever so it is positioned at 90 degrees to the pipe which will close tank 1 outlet valve

- Lift man lid on tank 2

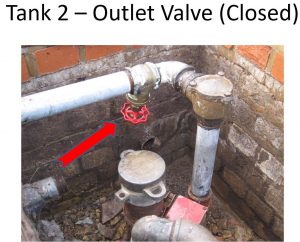

- Turn red wheel anti-clockwise (several turns) to open tank 2 outlet valve

- Replace both man lids – mind your fingers !

- Remove fuel nozzle and continue refuelling

Tank 1 – Outlet Valve (Open)

Tank 2 – Outlet Valve (Closed)

Switching Pumps

- If the pump in use (normally No.1) fails during refuelling

- Replace the fuel nozzle in pump No.1

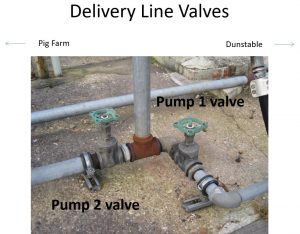

- Operate the round green gate valve on the Dunstable side of the filter vessel by turning clockwise – this shuts the valve on the No.1 pump delivery line

- Operate the round green gate valve on the Pig Farm side of the filter vessel by turning anti-clockwise – this opens the valve on the No.2 pump delivery line

- Take the dummy nozzle from pump No.2 (which will start pump No.2) and replace the fuel nozzle in pump No.1

- You should now be able to continue refuelling

- When refuelling is complete, replace the fuel nozzle in pump No. 2

Filter Vessel – Daily Fuel Checks

- Use the correct sample jar for the day and empty the previous week’s fuel sample into the waste Avgas jar.

- Use clean tissue to wipe the inside of the jar to remove any particulates and water droplets sticking to the glass from the previous sample.

- Operate the water drain into the jar WITHOUT the pump running – this should result in a small amount of fuel in the jar before the flow stops and should clear any free water in the filter vessel – discard into the waste Avgas jar.

- Remove the fuel nozzle from the pump which will start the pump and pressurise the filter vessel. Take a sample from the water drain at full flow to at least half fill the jar.

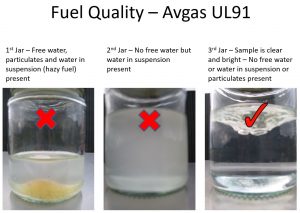

- Put the lid on the jar and allow the sample to settle for a few seconds.

- ‘Swirl’ the fuel in the jar so that a vortex forms – this will help to collect any particles or free water on the bottom of the jar at the base of the vortex.

- If free water is observed or the sample is hazy (water in suspension) repeat the sampling process until a clear and bright sample is observed.

- Note – A small number of rust particles in the sample seem to be ‘normal’ at Dunstable.

Miscellaneous

- Remember to attach the earthing cable to an unpainted metal part of the aircraft to dissipate any static electricity BEFORE the fuel nozzle comes anywhere near the aircraft

- Do not leave the aircraft unattended while you are fuelling. Occasionally the automatic fuel cut-off mechanism in the nozzle doesn’t !!

- Take care with the position of the nozzle in the aircraft to avoid fuel pouring out of the fuel overflow pipe as you are fuelling

….and don’t forget the paperwork !

Back to ‘Equipment’ Back to ‘Front Page’